Stitching

Setup for Construction

Having cut out all the pieces, I built a jig the shape of the middle bulkhead to temporarily screw the side panels to, and to position the bottom panels.

The Middle Bulkhead Jig, Clamped to

Middle Bulkead for sizing.

Then I built a strongback out of 2x4's to hold the jig and the transom

The Strongback

Assembling the Panels

On

attaching the the side panels to the transom and the jig it was obvious

that I didn't allow for the rocker of the boat and needed some

clearance between the transom and jig and the strong back so I could

connect to the bow --duh!

Jig and Transom Elevated

Bow Tied In

First Bottom Panel Tied In

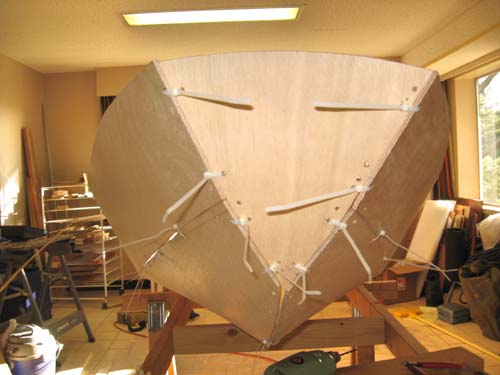

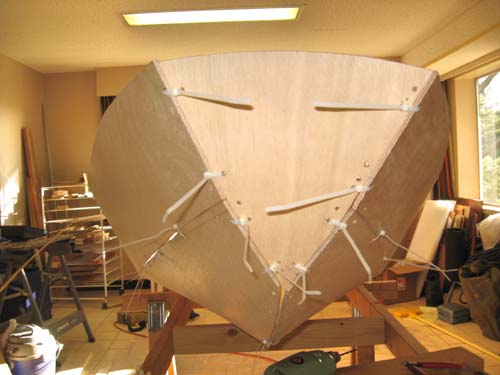

So to make a long story short I tied in all the panels with ties about every 8" along the seams.

The Seamy Side of the Struggle

Ugly Gaps #1

Ugly Gaps #2

The initial result wasn't too pretty, being some distance from the desirable 1/4" gap all around. There were lots of wood to wood "hard point" contacts. But at least it was looking something like a boat. I turned it over and went to work.

Beginning to Shape Up

After

a fair amount of wrassling with the plywood, tightening, loosening it

began to shape up. Chunks of scrap plywood as temporary spacers were

some help, Short lengths of 1/2" PVC pipe looped in with the tie wraps

helped get the spacing right in some of the difficult spots. This was a

tip I picked up somewhere in the Bateau Forums. I used quite a few to

start, but as it started to shape up I was able to eliminate most

of them.

The Bow Much Improved

A this point the diagonal measurements--transom to bow opposited corners are about 1/2" difference. Its been quite a struggle to get to this point. It may be best to be content with this. The next step will be to tape the outside of the seams with duct tape and start the process of filleting and glassing the inside of the seams.

<previous | home |next>

The Bow Much Improved

A this point the diagonal measurements--transom to bow opposited corners are about 1/2" difference. Its been quite a struggle to get to this point. It may be best to be content with this. The next step will be to tape the outside of the seams with duct tape and start the process of filleting and glassing the inside of the seams.

<previous | home |next>