Start of the FB11 Build

Layout

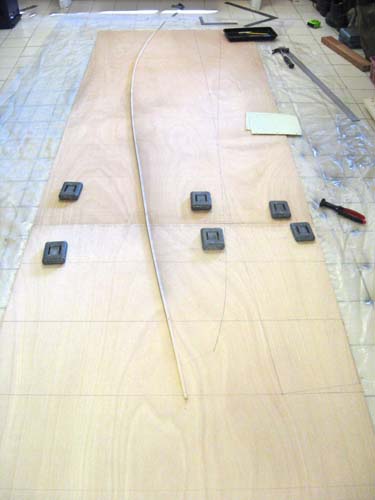

Having got some confidence from the geranium planter, I was itching to start on the main event. It took a week for the expoxy to get here (at non-prohibitive shipping cost) so I started on the layout. I drew lines every 12" along the the panels. There were some curves to draw, and the advice was the smoothness counted more than absolute accuracy. Points were given every 12''. So I got a piece of 1/2" quarter-round and drilled a hole in it every 12", and tacked it to the panel so the edge passed through the specified points and drew the curves.

Quarter-round layout spline in use

Joining the Panels 4/23/08

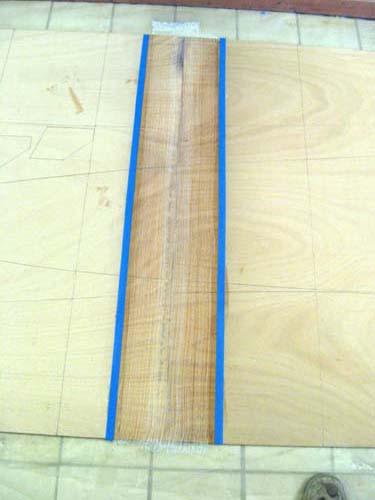

The sides and bottoms of the boat are longer than the 96" of the panels, so they have to be joined together. After getting assurances trom the forum, I went with a simple fiberglass joint rather than a more elaborate scarf joint, which would have been very challenging to my woodworking skills ahd equipment. This is just a matter butting the panels together and laying down a couple of layers of fiberglass with epoxy across the joint on each side of the panels. The epoxy and fiberglass arrived so I started in.

The Fiberglass Joint

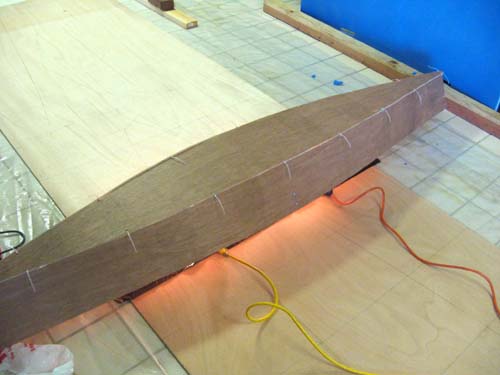

The expoxy promptly caught a cold, which is to say the weather turned cold here in sunny California. It stayed in the low 60's for several days. The morning after the first side joint was made, the epoxy was still pretty soft. This wasn't helped by the slow-set hardner I chose to get. I am working on a tile basement floor which isn't any too warm even if the room is. So I built a sauna for the joint.