A Jig for Scallop and Dam Hollowing of a Bamboo Fly Rod

byIt is useful to consider hollow construction for a bamboo fly rod to reduce its overall weight, and to reduce its swing weight or longitudinal moment of inertia. At the point in the construction where I would do this, I have split the bamboo into strips, straightened them, dealt with the nodes, rough beveled, and planed them to final taper. This is a lot of work. The possibility of ruining a strip doing the hollowing was much on my mind as I looked around for info on how to do it. Nothing I found in the rodmaking literature I have on hand, or online, spelled out how to do it to my satisfaction. So I had to resort to invention.

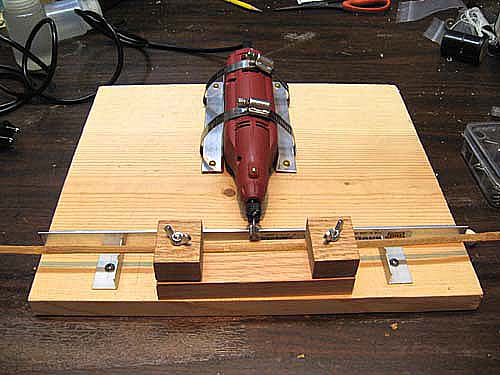

The Big Picture

Seen here is a baseplate with a rotary tool such as a Dremel with a milling cutter and a carrier block. There is a fence and stops to control the position of the carrier block with respect to the cutter. The rotary tool shown here is from Harbor Freight. The cutter is from a type 115 High Speed Cutter from Dremel. I currently recommend a 1/4" ball nose double cut carbide burr, with a 1/8" shank from Carbide depot. It stays sharp longer and doesn't seem to load up with bamboo gum like the Dremel item does.

The Baseplate

The rotary tool is held in place with two ¾" aluminum channel rails and two hose clamps. The fence and and stops for the carrier block are more ¾" angle.

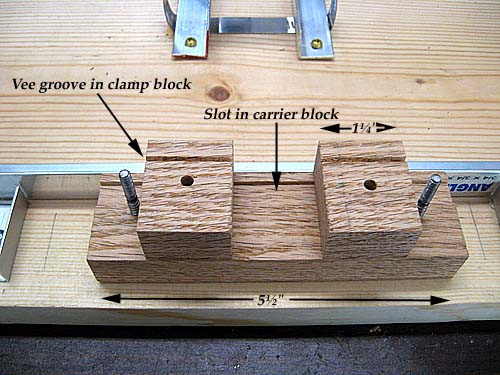

The Carrier Block and its Clamp Blocks

The carrier block is a piece of ¾" x 1½" (nominal) red oak. The cutter was used to mill a slot such that a scallop cut would have a wall thickness of 0.070". Altenatively one can mill the bottom of the block to get the 0.070 cut depth. A thinner wall thickness would result with a shim under the block. The clamp blocks have a vee groove milled in them using a 30° milling cutter, (type 125 High Speed Cutter) and are held down in use with wing nuts. The size of the block and the location of the stops is such that the scallop cut is 2½" long

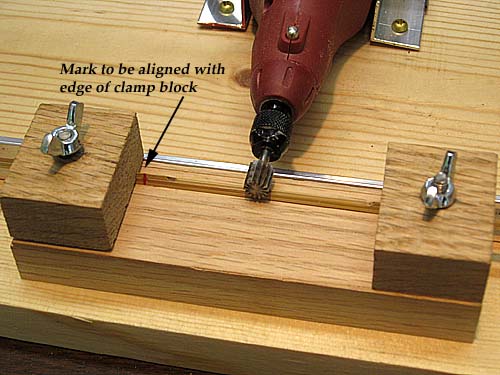

Alignment Marks

The strips are marked every 3". This is the length of one scallop cut and its dam

In Use

The marks of the strips are aligned with the edge of the clamp block. In the picture it is slightly offset to show the mark. The length of the resulting dam is the spacing of the marks less the 2½" of the cut. I used a 3" spacing. I found it was best to start the cut at the right end due to the counter-clockwise rotation of the cutter--starting from the other end will tend to lift the apex of the dam as you reach the right end. My procedure was to start with block against the left stop and push it in against the fence. The cutter will cut on its end surface. Going back and forth between the stops two or three times gives a nice cleanly finished surface. Then I remove the block with the strip from the baseplate, loosen the clamp blocks, move the strip left to the next mark, tighten and do it again.

Hollowed Strips

Here's some finished strips. Making a three piece rod, I hollowed the butt and the mid sections. I arranged it so that the nearest scallop to a ferrule was 2" away, but I hollowed all the way down to the butt end under the rod seat.

To shorten the length of the scallops the stops would be moved closer. To increase it a longer carrier block would be needed and the stops would be moved further apart.