A Chuck for Boring Cork

byMike McGuire

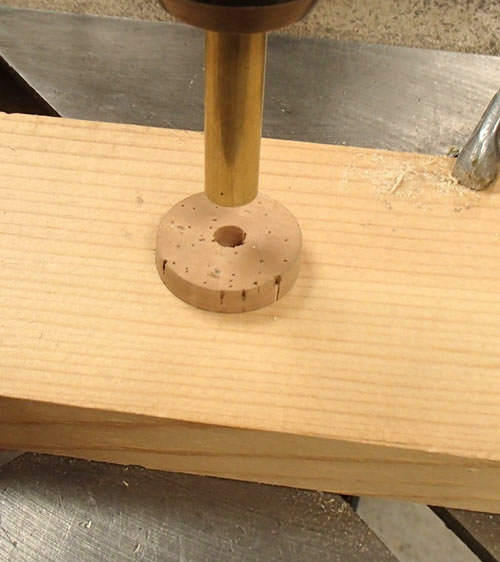

The cork rings come at a nominal diameter of 1.25". A simple setup that will work is to bore a 1.25" flat bottomed hole with a Forstner bit in a piece of wood clamped to a drill press and set the cork ring in the hole and drill it with the core drill. as shown here.

This works but is not my preferred way to do it.. Some cork rings come slightly off dimension, either over or under, which makes the setup hard to use. The corks in place on a rod blank tend not to be as straight as I would like. This can be taken up with more clamping force on the grip at glue up, but I don't care for this. My solution is a cork chuck used in my lathe. The starting point is a 1" nominal diameter PVC screw thread pipe cap.

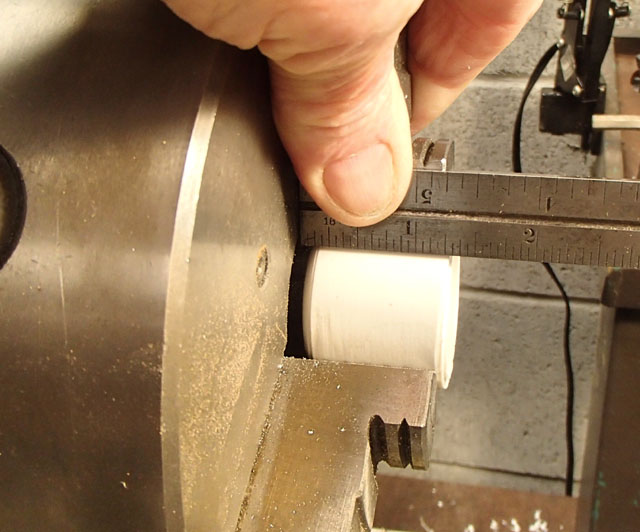

I say 1" nominal because is actually about 1.6" outside diameter, 1.150" inside diameter. The 1.0" is the inside diameter of the pipe on which it would be used. It is necessary to machine the outside to remove the ribs and ring which would interfere with the chuck function. The easiest way to hold it to machine it is to screw it onto a pipe fitting that is easier to hold in the lathe chuck as shown here.

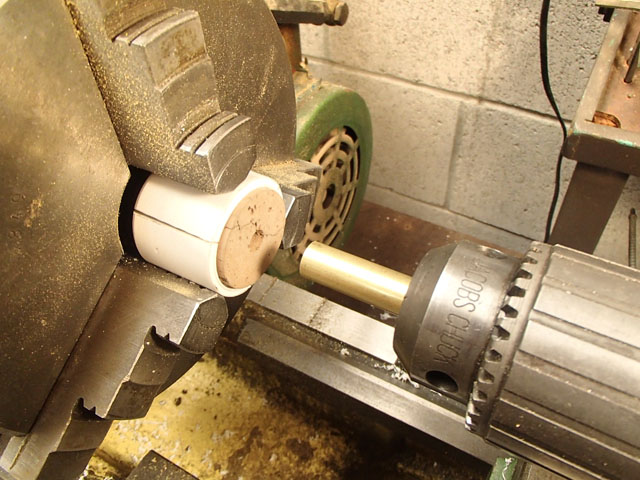

Here the ribs etc. have been machined off, the end faced flat, a 1/2 " diameter circle scribed in the end, and small hole for a screw bored in the center.. Next the cap is reversed in the chuck, and the screw thread machined away to a diameter of about 1.28". Using the chuck jaws as a guide, three equally spaced lines are drawn on the cap.

The cap is sawed on the marked lines to the 1/2" circle marked on the back.

Here is the finished cork chucK. A 1/2" thick by 1" diameter wood disk is mounted in it with a screw through the hole in the back. This makes a surface for the core drill to exit the cork without tearing and to get the cork ring square in the chuck.

Here is the chuck in use. The slits are about halfway between the chuck jaws.

Couple of final tips--Clean the core of the drill after every cut or it may mess up the next cut. It may be that a cork rings with a smaller hole than the standard 1/4" are needed. Cut some cores with a 1/4" inside diameter core drill from a sacrificial ring, and glue them into the rings. Then drill them to size.